Smart manufacturing

What is it about

Improving substantially productivity, quality and safety in manufacturing companies, is what ImecTools-IoT can do.

With fast and sustainable results, affordable to both large industrial companies and small manufacturing businesses. Companies that seek excellence in their production processes, taking into account the human factor, in order to be more successful in their markets.

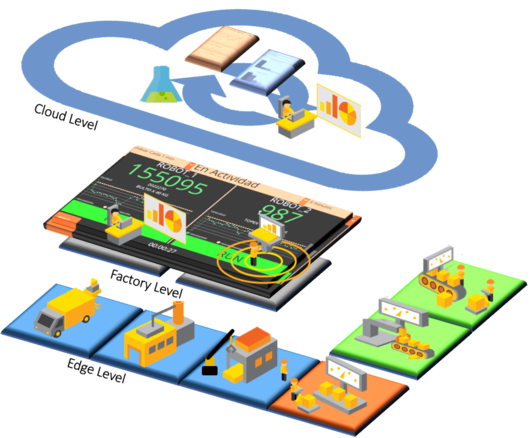

Our platform integrates multiple modular IoT-applications, running across many important production processes.

We make emphasis on enhancing operators’ skills in real time. Operators will continue to be the ultimate driver for competitiveness.

Operators will continue to be the ultimate driver for competitiveness. When they have the support, feedback and insight to be more effective and secure, operators will be empowered.

ImecTools-IoT provides a platform to bring major manufacturing 4.0 benefits in a cost-effective and scaled-up solution.