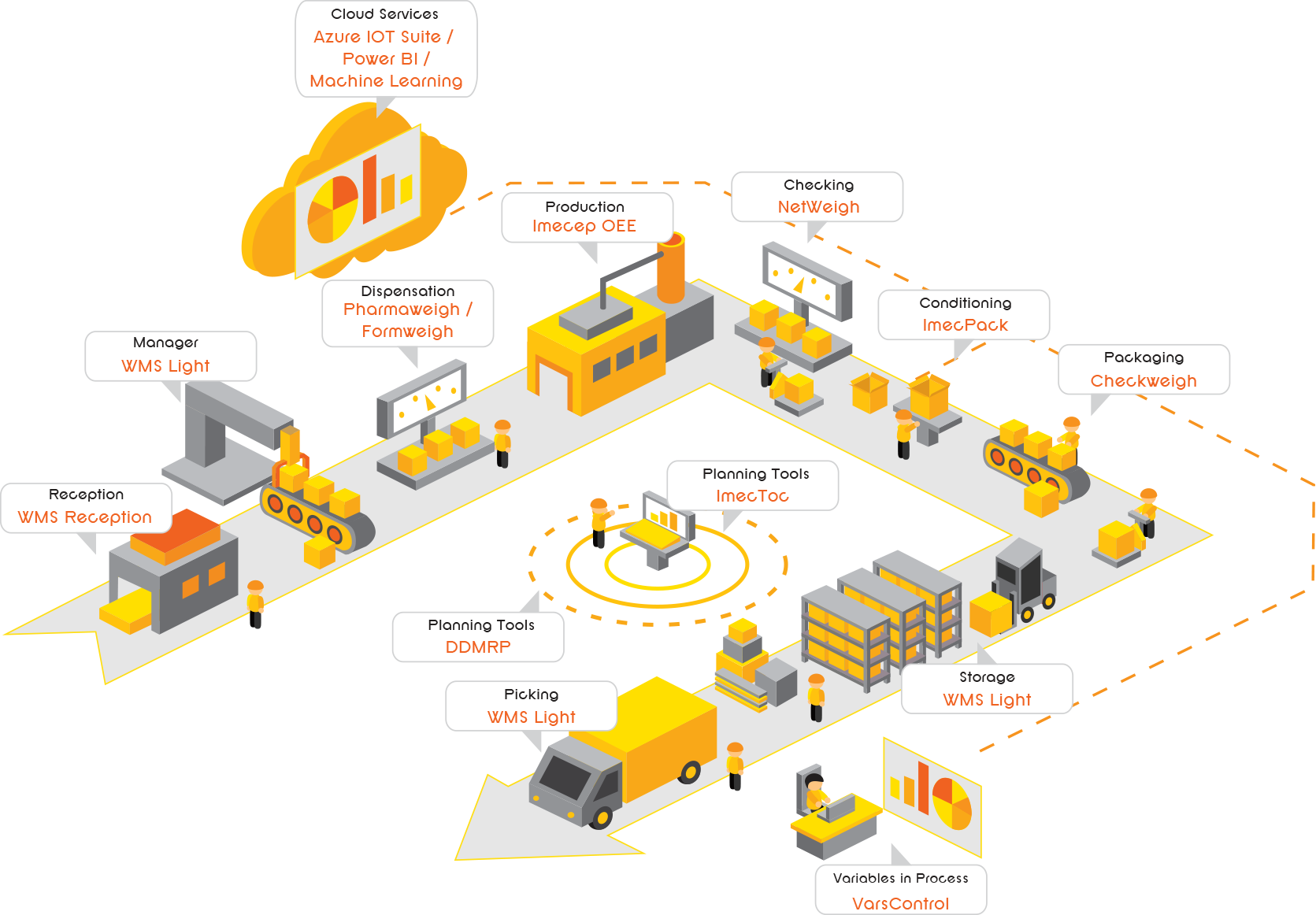

Manufacturing Platform 4.0

ImecTools now is ImecTools-IoT: A powerful and well proven suite of modular manufacturing IoT- Solutions designed to optimize productivity and overall quality.

They apply the best-known improvement methodologies, as they capture the process data. They provide feedback to operators and visualization throughout the company’s organization for the most important production processes.

Now extended capabilities through smart or 4.0 manufacturing data technologies, enabling all sizes companies to benefit immediately from the new era in manufacturing.