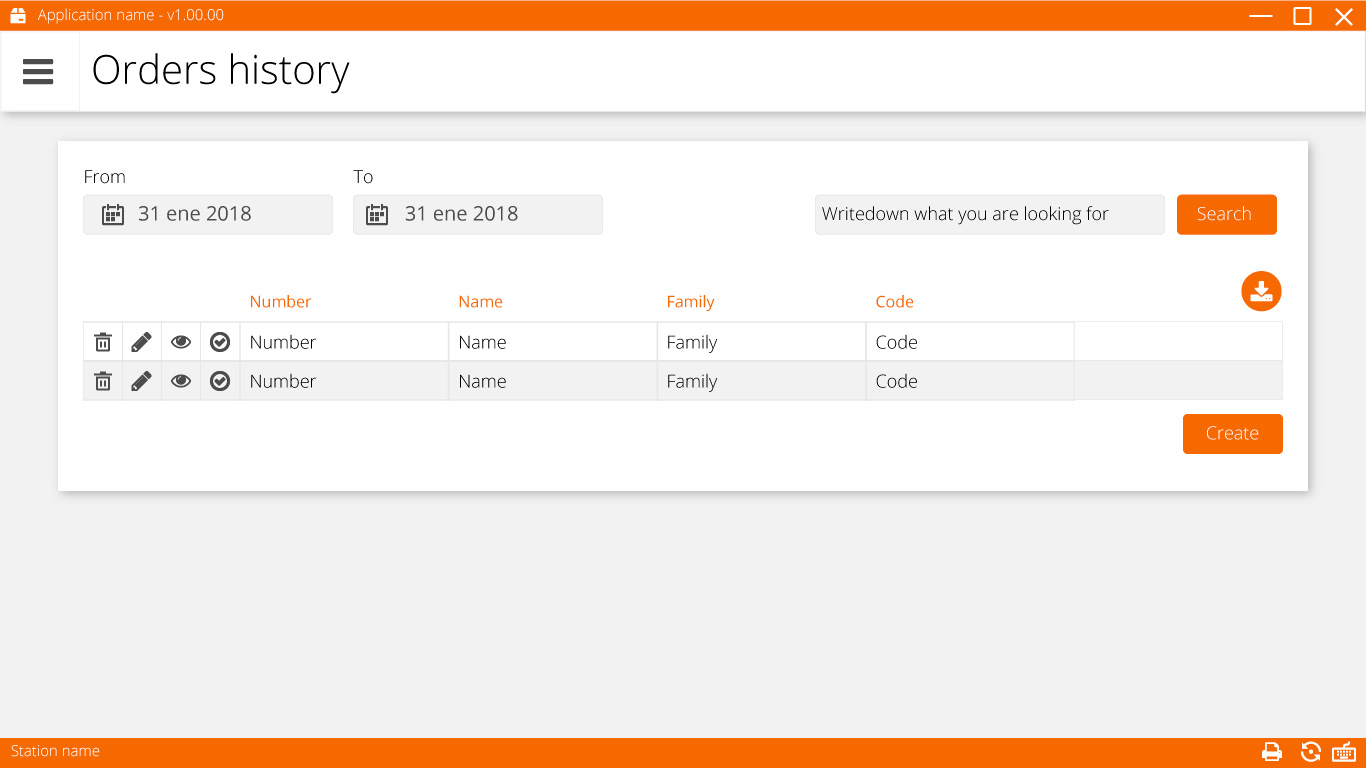

Packing improves the profitability, quality and production time by controlling the execution and enlistment of orders by capturing weights directly from scales or machines and real-time feedback to the operators with our technology of synchronization and centralization of the information without the variations of quality in the network affects the operating lines.

Assuring Packaged units and traceability

Benefits

It reduces the operational costs associated with the natural variability of processes such as waste, overfilling, time taken for data collection, audits, administrative processes, and manufacturing re-processes. By achieving a sustainable standardization of the process of enlisting and conditioning orders through weighing control improves decision making by providing accurate data in real time and substantially decreases the risks of non-compliance or penalties for non-compliance with legal regulations.

Studies show that many companies are often unaware of the true magnitude of the cost of waste in conditioning processes. It is not uncommon to find that it can be more than 5 times higher than they had calculated.

STANDARDIZED PROCESS

It achieves a standard process of isolation and sustainable conditioning that guides the control of weighing leading to important savings by reducing errors or re-processes.

RISK REDUCTION

Substantially reduces the risk of sanctions for non-compliance of industry’s standard laws.

LOWER COSTS

Reduces operational costs associated with data-collecting time, audits, administrative procedures, and manufacture reprocessing.

BETTER DECISIONS

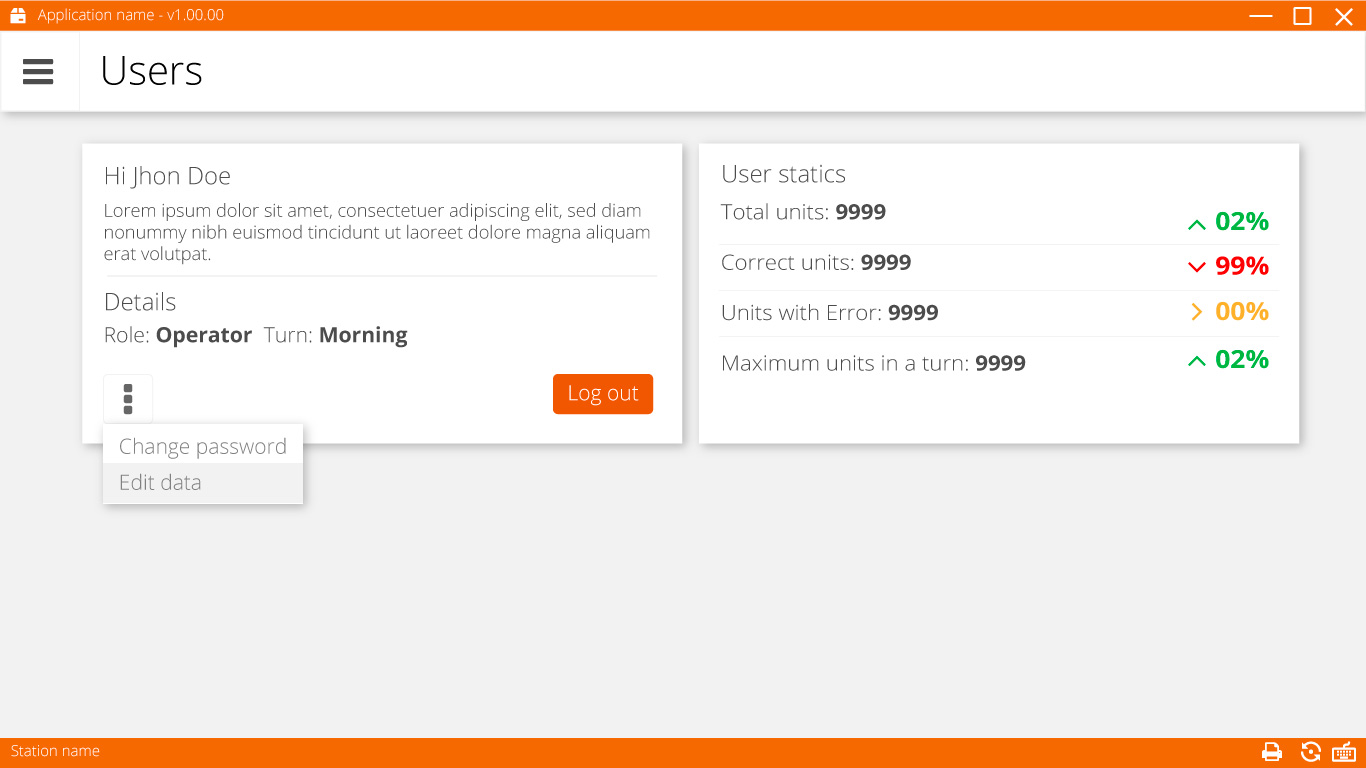

A good, clean data capturing process can be easily transform in useful information in order to make the best decision at the perfect time.

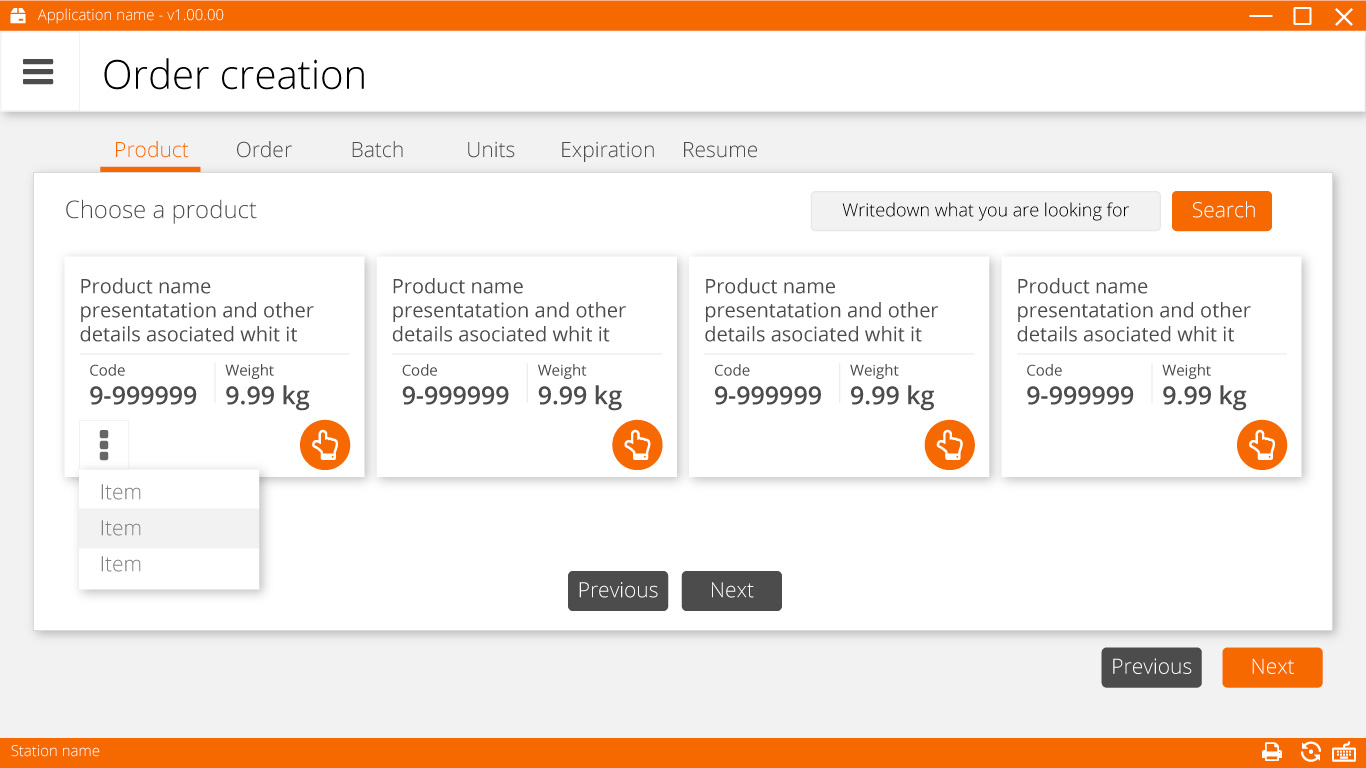

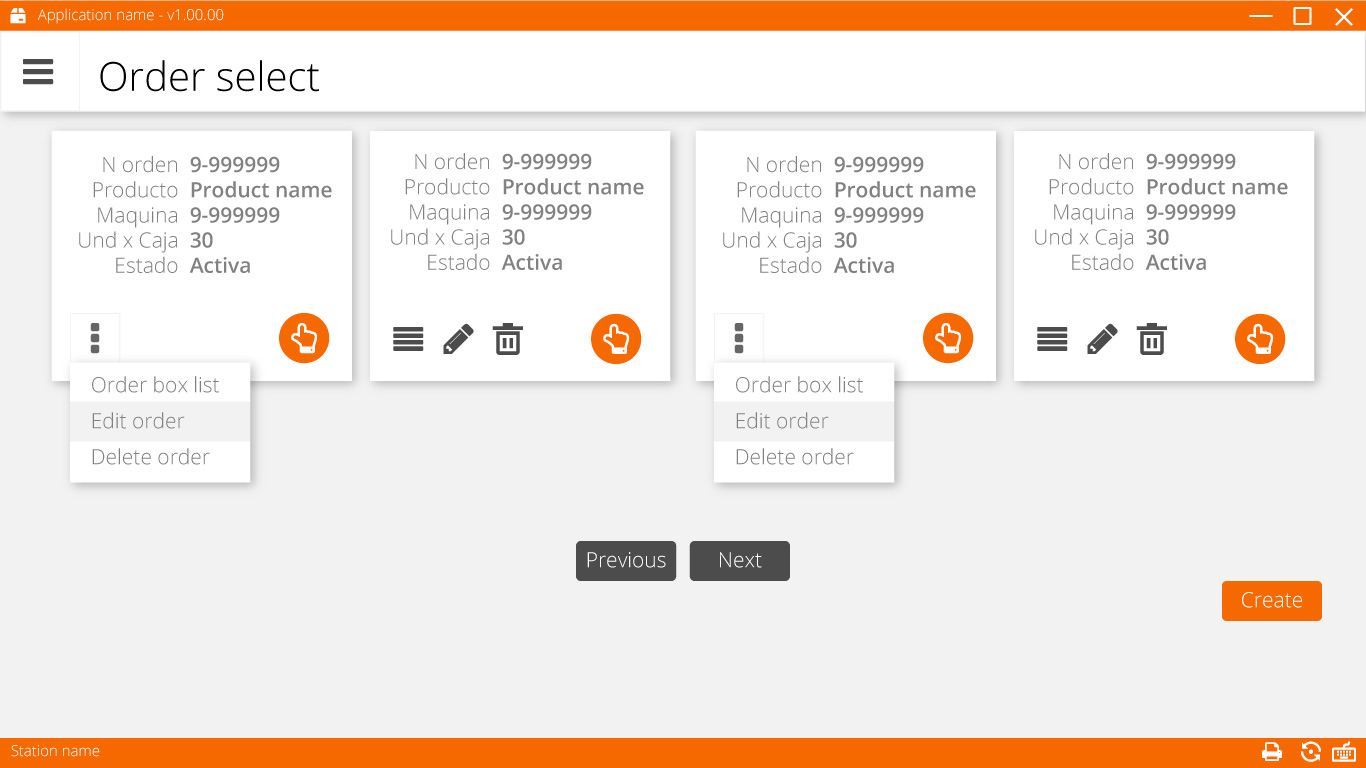

Packing is the software tool that simplifies the statistical control of quality and capacity measurement of the product conditioning process, allows to minimize waste and reprocessing as well as comply with regulations.

Packing has been designed to easily adapt to different manufacturing environments, with the aim of achieving results immediately after installation.

More tools

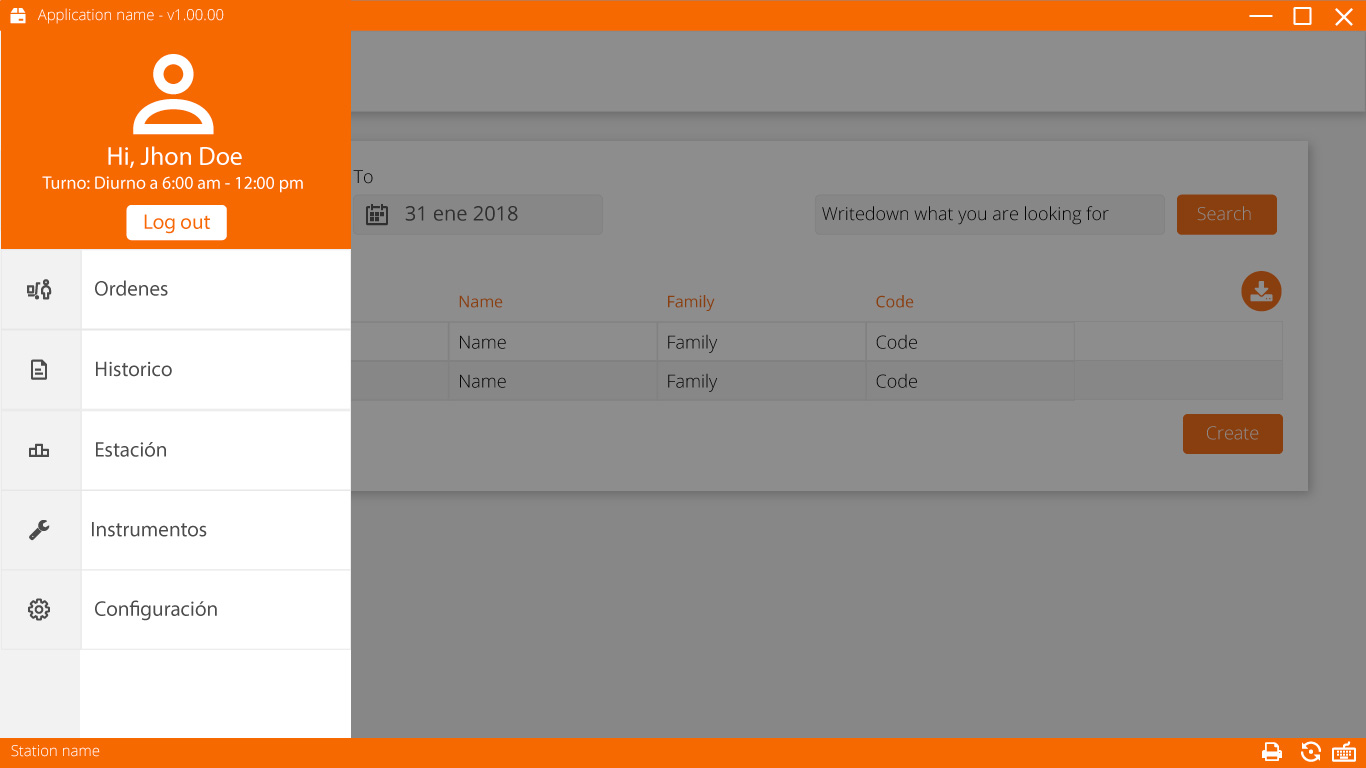

NetWeigh is part of the ImecTools Suite developed by Imectech, a set of products and tools that have been carefully designed to provide advanced real-time statistical analysis in a simple way so that everyone, from machine operators, to quality control supervisors and factory managers, can make better, more informed decisions regarding the process that’s being carried out.

Learn more about the other ImecTools within the Suite, and get what you and your business need.