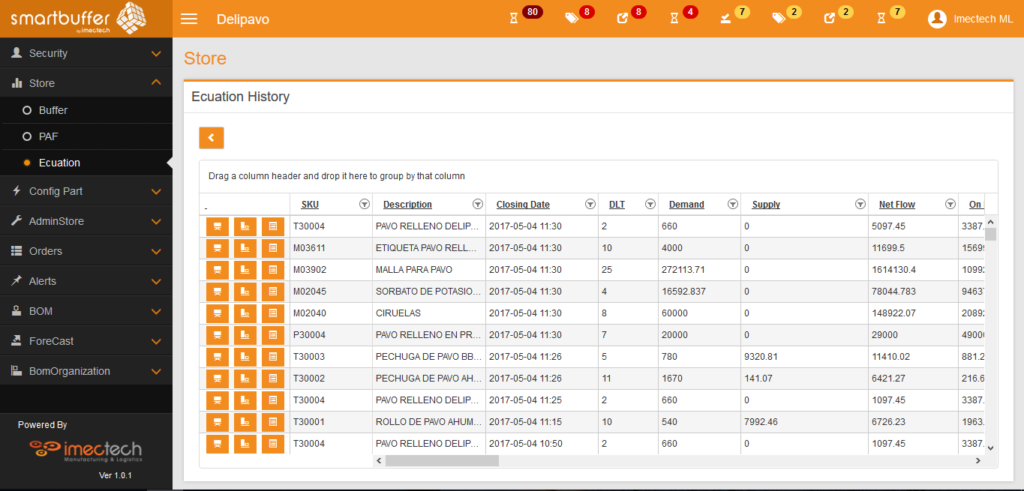

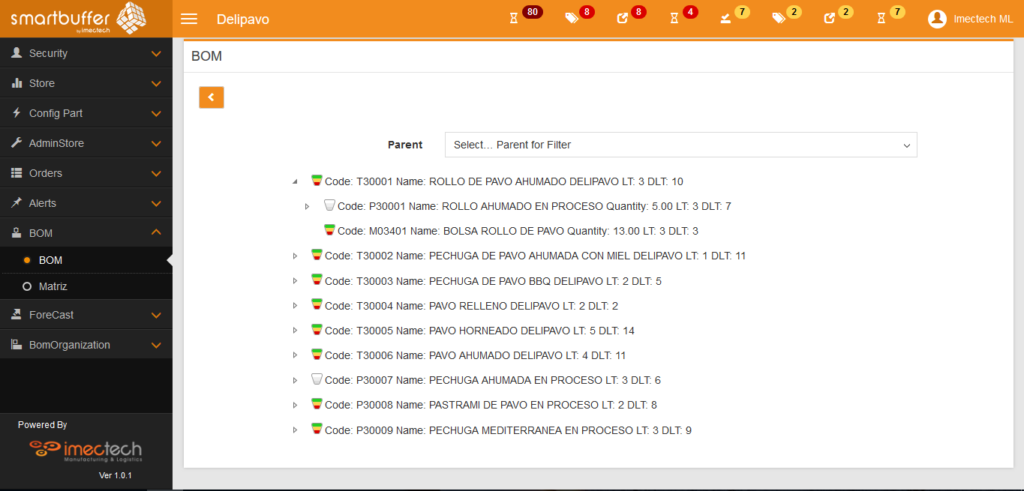

Even the smallest companies have dozens of suppliers, hundreds of references to finished products, which are manufactured in a production facility that uses dozens of resources with multiple production lines, industrial operations and even more customers.

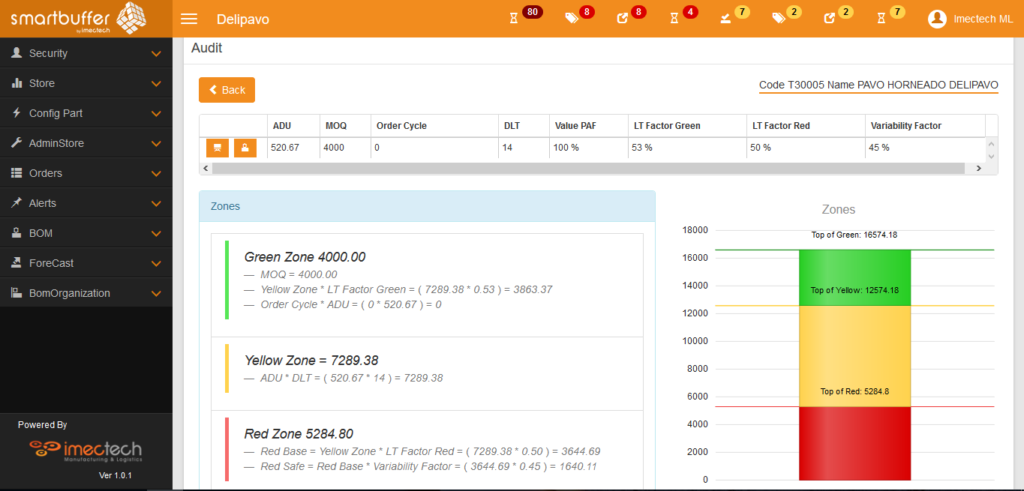

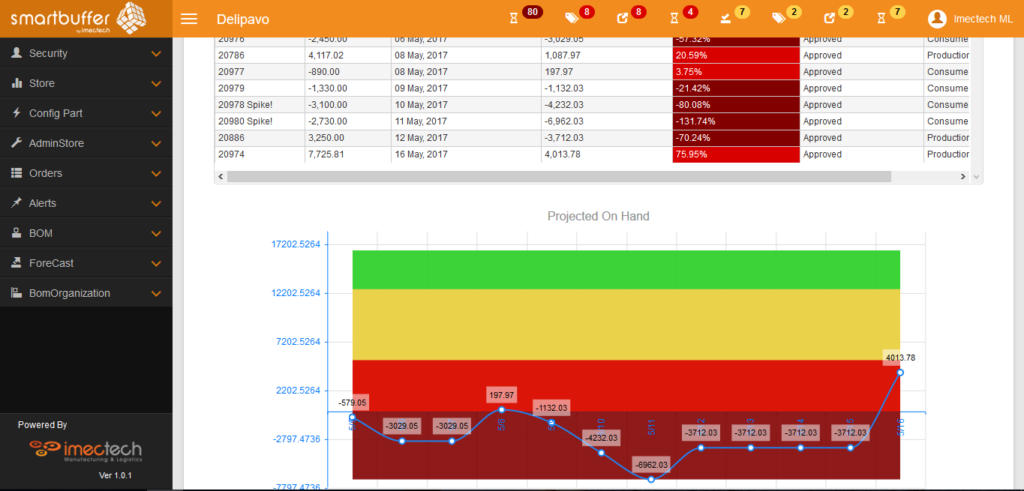

DDMRP (Demand Driven Material Requirement Planning). It is a very useful methodology for manufacturing companies, in which the management of inventories is a critical issue due to its impact on the performance of the operation as well as the financial cost and profitability of the business.