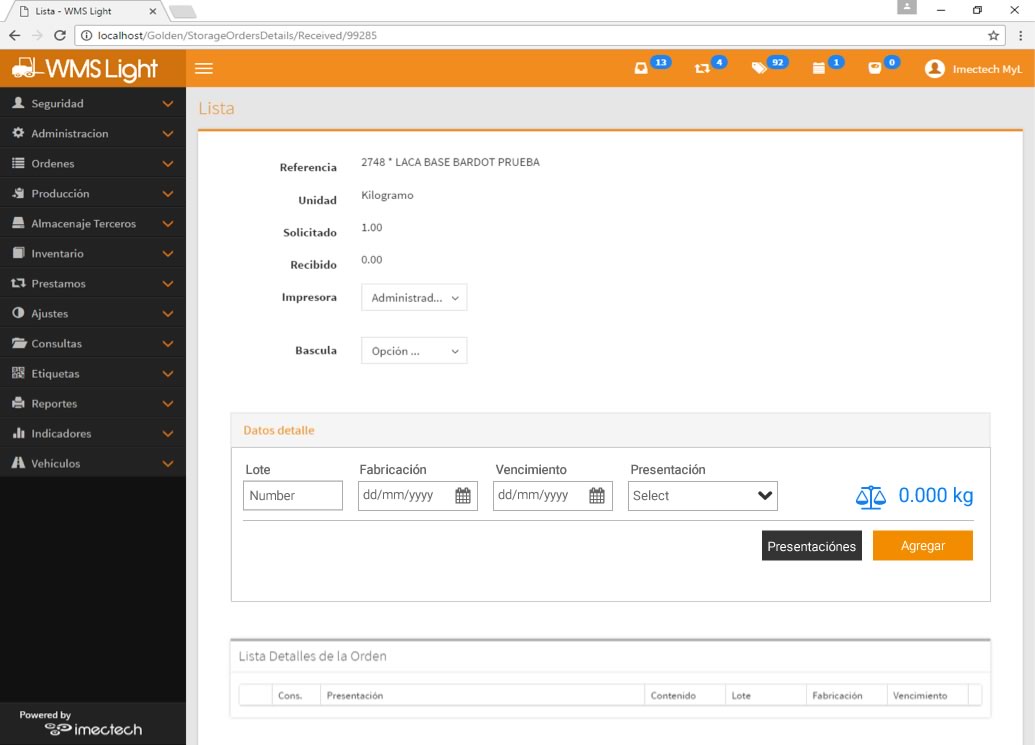

Unify material flow information while maintaining precise control of your company’s inventory values and information on the movement of inputs and products within your storage area by recording physical movements of products and raw materials, follow the traceability in flows and retain them for subsequent database queries.

Effective Solutions to Common Problems

Benefits

Imectech’s WMS system allows to reduce costs and optimize the warehouse management processes by implementing storage space improvement methods, by means of an adequate management of locations and methods of managing movements or material flows, either by machines or by people.

- It manages material movements of both finished product and first materials, packaging material and spare parts, reception orders and goods.

- Due to its flexibility it adapts to any sector and has a module for the control of serial numbers, batches and expiration dates.

- Completely manages the traceability of the entire production process and / or distribution and expiration dates.

- Works with both “Paper” and RF technologies, pick / put to light, pick by voice, RFID, etc.

- Multi-warehouse, multi-area and multi-company management.

Collaborates with the planning, management and execution of routes in the flows of the merchandise. - Identification and control of merchandise through multiple 1D and 2D barcodes and through RFID.

- Advanced management and control of automated transportation systems and equipment.

- Management and automatic location of goods guided by flows.

Management of multi item, multicontenedor, multiformat and mono format locations. - Advanced and optimized system of order picking multi-method, reverse picking with waste management.

It is the specialized software tool developed by Imectech Solutions for the control and management of inventories in production plants and companies that have different volumes of material in their facilities and need to coordinate and manage the dynamics of storage in their establishments.

More tools

The WMS storage management system is part of the ImecTools Suite developed by Imectech. These products and tools have been designed to provide advanced real-time statistical analysis in a simple way so that from machine operators to quality controllers and factory managers can make more informed decisions regarding the process that is carried out .

Learn more about the Suite’s other tools, and get what you and your business need.